Hello!

My name is Mike and I apologize if this is the wrong forum for this, but I didn’t see another more applicable. I feel the need to introduce myself because I am sure I will be asking you fine folks questions rather frequently as I struggle to make my T3-TB into the box that I want it to be.

I’m a refrigeration service engineer by trade on the east coast of the USA with 13 years in the industry doing supermarket refrigeration & EMS. I primarily deal with Danfoss equipment and have become very proficient at it. I’ve worked extensively on everything from the Z-panel to the 880 doing service work and control overlays. I know my way around a building controller, but I’ve never had to build the logic from scratch.

Danfoss makes good equipment, but it’s expensive. I have many smaller customers (restaurants, churches, etc.) who have walk-in boxes and other equipment that they would like to have monitored for temperature alarms, but giving them a price of $3k+ to install an 880 and the necessary boards is simply cost prohibitive. In addition, not everything I’d like to control comes as a built-in feature. Some things still be need to be run from custom ‘calculations’ as they are referred to by Danfoss.

When I stumbled across the T3000 controller, I got excited! I had found what appeared to be a very capable little controller for a very reasonable price. Four-days later it’s hooked up and reading a 10k sensor on my desk! It’s not much, but it’s a start.

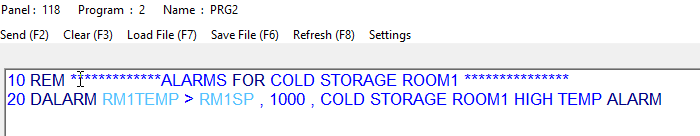

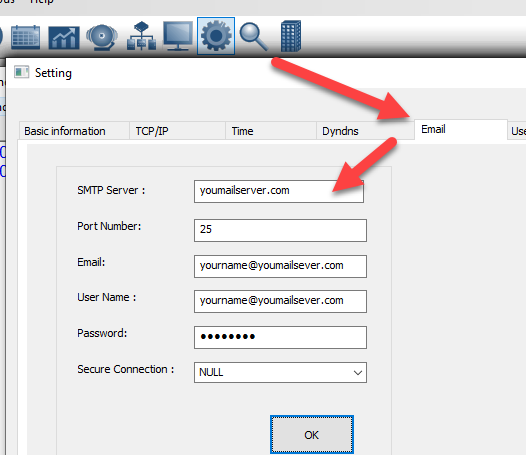

My current vision for the box is for it to be a walk-in controller capable of emailing temperature alarms using a tablet PC as the front end so the owner can have a nice little visual display and so the service tech doesn’t need a laptop to change set points (the vast majority of techs are not sophisticated enough to deal with this sort of thing).

From looking at the programming examples it looks to me like I will have to set things up the following way:

Inputs: Box temp sensor, evap coil sensor (for defrost termination), possibly a box-door switch (to kill fans on a freezer when someone opens the door).

Outputs: compressor, defrost relay, fans, lights, alarm strobe

Variables (where I will need the most help):

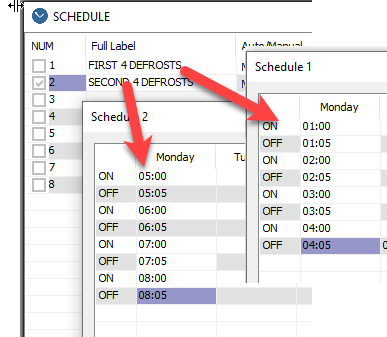

Time (A box has to defrost at a set interval / based off the temp of the defrost termination sensor)

Target temp (desired box temperature)

Differential ( cut in / cut out for condensing unit. Ex: Target 32f with differential of 2 cuts in at 34 and out at 30)

Defrost Duration Min / Max (if something happens to the termination sensor, the box will defrost for a minimum of X amount of time, but will terminate on temperature after that minimum has been exceeded OR will continue to defrost until the MAX time has been reached)

Termination temperature (the system should cancel defrost and return to cooling after a set temp is reached either by the space temp OR termination sensor reading)

Alarm Delay (If box temp is 48f > for 60 minutes then energize alarm relay)

I’m sure I’ve forgotten something, but basic control is all I’m concerned with at this moment. I apologize in advance for asking what many of you guys who are comfortable writing code will consider dumb questions. I just ask that you bear with me while I struggle!

I am looking forward to the experience!