Similar to the outdoor temperature reset formula, you have the two points and will need to dig way back to middle school math to generate a general forumula for a line between two points.

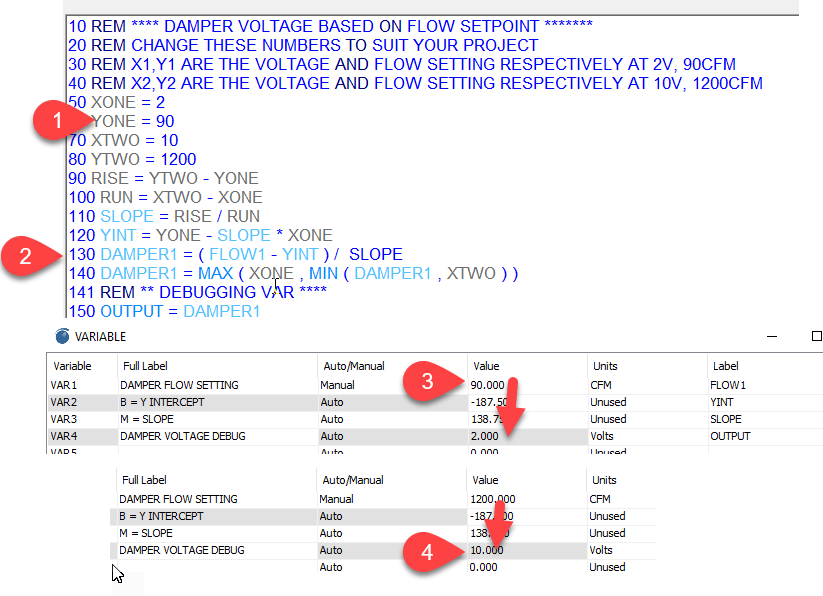

10 REM **** DAMPER VOLTAGE BASED ON FLOW SETPOINT *******

20 REM CHANGE THESE NUMBERS TO SUIT YOUR PROJECT

30 REM X1,Y1 ARE THE VOLTAGE AND FLOW SETTING RESPECTIVELY AT 2V, 90CFM

40 REM X2,Y2 ARE THE VOLTAGE AND FLOW SETTING RESPECTIVELY AT 10V, 1200CFM

50 XONE = 2

60 YONE = 90

70 XTWO = 10

80 YTWO = 1200

90 RISE = YTWO - YONE

100 RUN = XTWO - XONE

110 SLOPE = RISE / RUN

120 YINT = YONE - SLOPE * XONE

130 DAMPER1 = ( FLOW1 - YINT ) / SLOPE

140 DAMPER1 = MAX ( XONE , MIN ( DAMPER1 , XTWO ) )

141 REM ** DEBUGGING VAR ****

150 OUTPUT = DAMPER1

Here’s a screen shot of what you’ll see in T3000. I have saved the prog file at the link below for loading into your own controller there. The grey items in the program are local variables which are help only in memory of the T3 controller. The blue items are global variables which we can see in the vars table.

VAR1 is the flow setpoint in CFM, you can set this to metric or other units by clicking on the range column and selecting from the various built in ranges or make your own.

Notice that VAR1 is in manual mode for now, this lets you set the flow setpoint manually to watch what happens with the damper output voltage math. Setting it to 90CFM sends the damper to 2V at Tab3 and setting it to 1200 sends the damper voltage to 10V.

Line 140 clips the damper voltage to the minimum of 2V and the maximum of 10V.

Line 150 is just for easy debugging and can be deleted once you are done with it, this var lets you temporarily mirror the damper voltage from the outputs table in the vars table while you are testing.

The difference between this example and the outdoor reset example is we’re varying the air flow, the Y parameter and solving for the X parameter, the damper voltage. So the math in line 130 solves for X in this example.

Here’s the prog file, this is done on a T3-BB so you will need to move the DAMPER1 on output13 to a spare analog output on your particular hardware.

FlowSetpoint_DamperVolts.prog (65.6 KB)